Concrete Slump Test: Measurement Method and Its Importance

The concrete slump test is one of the most critical tests for evaluating the workability and flowability of fresh concrete. This test indicates the fluidity and moldability of concrete before it sets, helping engineers ensure the concrete is suitable for its intended application. In this article, we explore the slump test procedure, required tools, types of slump, and key considerations. For more details on modular formwork, visit Concrete Formwork.

What is the Concrete Slump Test?

The concrete slump test measures the consistency and flowability of fresh concrete. This quick and straightforward test assesses the concrete’s ability to fill molds, flow around reinforcements, and compact properly without segregation or separation of its components. The slump value, reported in millimeters, depends on factors such as the water-to-cement ratio, material types, admixtures, and ambient temperature.

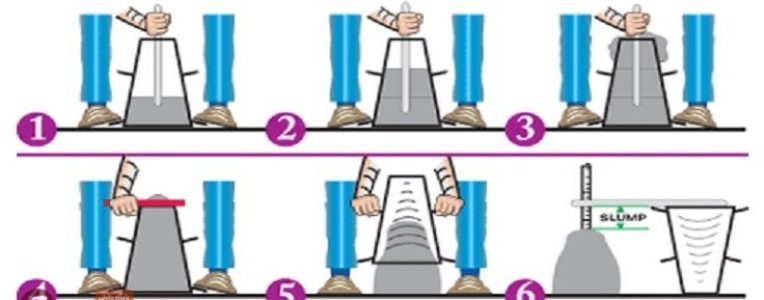

Concrete Slump Test Procedure

The slump test is conducted according to international standards such as ASTM C143 or BS EN 12350-2. The procedure is as follows:

Required Tools:

- Slump Cone: A metal cone with standard dimensions (height: 300 mm, base diameter: 200 mm, top diameter: 100 mm).

- Base Plate: A flat, non-absorbent (usually metal) plate for placing the cone.

- Tamping Rod: A metal rod (16 mm diameter, 600 mm length) for compacting the concrete.

- Ruler or Tape Measure: For measuring the slump height.

- Scoop or Trowel: For filling the cone with concrete.

- Bucket or Container: For transporting the fresh concrete sample.

Steps of the Slump Test:

- Prepare the Tools: Clean the slump cone and base plate, and lightly moisten them to prevent concrete from sticking.

- Place the Cone: Position the cone on the base plate and hold it firmly in place with your feet or hands.

- Fill the Cone:

- Pour fresh concrete into the cone in three layers (each approximately one-third of the cone’s height).

- Tamp each layer with 25 strokes of the tamping rod. Strokes should be uniform and penetrate the underlying layer.

- Level the Surface: After filling the cone, level the concrete surface with a trowel.

- Remove the Cone: Gently lift the cone vertically in 5 to 10 seconds.

- Measure the Slump:

- Place the cone next to the concrete.

- Using a ruler, measure the distance between the top of the slumped concrete and the top edge of the cone (original height: 300 mm). This distance is the slump value.

Types of Slump Based on Shape:

- True Slump: The concrete subsides uniformly while retaining a conical shape. This is the desired slump for most projects.

- Shear Slump: Part of the concrete shears off, indicating a lack of cohesion. The test should be repeated.

- Collapse Slump: The concrete completely collapses and loses its shape, indicating excessive flowability (often due to too much water).

Slump Values and Applications

The slump value varies depending on the project and concreting method. The table below lists typical slump values and their applications:

| Slump Type | Slump Value (mm) | Application |

|---|---|---|

| Stiff | 0–50 | Road paving, simple foundations, precast concrete |

| Semi-Stiff | 50–100 | Slabs, columns, walls with moderate compaction |

| Flowable | 100–150 | Pumped concrete, heavily reinforced structures |

| Highly Flowable | 150–200 | Self-compacting concrete, complex formwork |

Note: A slump value exceeding 200 mm may lead to segregation, while a value below 50 mm reduces workability, making concreting difficult.

Factors Affecting Concrete Slump

- Water-to-Cement Ratio: Increasing water content enhances flowability and increases slump.

- Type and Size of Aggregates: Finer aggregates generally improve flowability.

- Admixtures: Plasticizers or superplasticizers can increase slump without adding water.

- Ambient Temperature: High temperatures reduce flowability and slump.

- Mixing and Transport Time: Delays in concreting may decrease slump.

Importance of the Slump Test in Construction Projects

- Quality Control: The slump test ensures the concrete has the necessary workability for proper mold filling and compaction. For more on modular formwork, visit Concrete Formwork.

- Cost Optimization: Concrete with appropriate slump reduces the need for excessive labor (e.g., over-vibration).

- Structural Safety: Improper flowability may cause voids or weaknesses in the structure.

- Compliance with Standards: The slump test helps contractors meet project specifications.

Key Considerations for Conducting the Slump Test

- Timing: Perform the test immediately after mixing (within 5–10 minutes) for accurate results.

- Proper Sampling: The concrete sample should represent the entire batch, taken from multiple points in the mixer or batching plant.

- Retesting: If a shear or collapse slump is observed, repeat the test.

- Environmental Conditions: Avoid testing in strong winds or on uneven surfaces.

- Tool Cleaning: Clean tools after each test to prevent residual concrete from affecting subsequent results.

Role of Modular Formwork in Concreting

To achieve optimal results in concreting, high-quality modular formwork is essential. These formworks, with their standardized design and reusability, facilitate concreting with appropriate slump values and prevent concrete leakage or deformation. For more information on modular formwork and its role in concrete projects, visit Concrete Formwork.

Conclusion

The concrete slump test is one of the simplest and most effective methods for assessing the workability of fresh concrete. It enables engineers and contractors to ensure concrete quality, compliance with standards, and proper performance during formwork filling. By selecting the right slump value and using high-quality modular formwork, the quality of concrete structures can be enhanced, and project costs can be optimized. For more details on tools and formwork required for concreting, visit Concrete Formwork.