A foundation, also known as a footing, is a vital structural element that transfers the loads of a building to the ground. Positioned at the lowest part of a structure, the foundation ensures the overall stability and strength of the building. It prevents sliding, overturning, and uneven settlement, acting as a critical interface between the superstructure and the soil beneath.

This comprehensive guide covers the definition of a foundation, its types, execution steps, essential formwork tips, and the role of advanced systems like

modular metal formwork,

plastic formwork systems, and

concrete formwork. Our aim is to provide detailed, actionable insights for engineers, contractors, and construction enthusiasts.

What is a Foundation and Why is it Important?

A foundation is the combination of structural elements and the underlying soil that transfers building loads to the ground. By evenly distributing these loads, it prevents excessive stress concentration and ensures structural stability. The strength of a foundation directly impacts the durability and safety of the entire building.

Key Functions of a Foundation

Foundations serve several critical purposes:

- Load Transfer: Transfers dead loads (building weight) and live loads (occupants, furniture) to the ground.

- Settlement Prevention: Distributes loads to prevent uneven settlement that could cause cracks.

- Resistance to Lateral Forces: Withstands earthquakes, wind, and soil movement.

- Stability Assurance: Prevents overturning or sliding under adverse conditions.

To achieve a robust foundation, using high-quality equipment like

modular metal formwork enhances precision and safety during construction.

Types of Foundations in Construction

The choice of foundation depends on factors such as soil type, load requirements, and environmental conditions. Foundations are broadly categorized into two types: shallow and deep.

Shallow Foundations

Shallow foundations are used in soils with high bearing capacity and are constructed at a shallow depth. Common types include:

- Strip Foundations: Ideal for load-bearing walls and lightweight structures.

- Spread Foundations: Distribute loads over a larger area, such as under columns or entire buildings.

- Isolated Foundations: Support individual columns with concentrated loads.

Deep Foundations

Deep foundations are employed in weak soils or for heavy loads requiring transfer to deeper, more stable layers. Types include:

- Piles: Transfer loads to deeper, stronger soil layers.

- Caissons: Suitable for large projects like bridges or high-rise buildings.

Steps for Executing a Foundation

Foundation execution is a precise process that must comply with national building codes and engineering standards. The general steps include:

1. Site Selection

The first step is selecting a suitable site for the foundation. This decision is based on soil conditions and the structural requirements of the building. Soil mechanics, which studies the physical and chemical properties of soil (e.g., bearing capacity, compressibility, shear strength), is critical here.

Some soils, such as loose sand or clay, may lack the strength to support heavy loads. Geotechnical tests like the Standard Penetration Test (SPT) or shear strength tests are conducted to determine the appropriate foundation type.

2. Choosing the Foundation Type

After analyzing soil conditions and load requirements, the foundation type (shallow or deep) is selected. This decision considers factors like building height, structural design, and project budget.

For large-scale projects, using

plastic formwork systems can streamline formwork and concrete pouring processes.

3. Foundation Boundary Demarcation

In this step, the foundation’s boundaries are precisely measured and marked. These measurements ensure the foundation aligns with design plans and confirm the suitability of the chosen foundation type. Tools like laser meters and theodolites are used for accuracy.

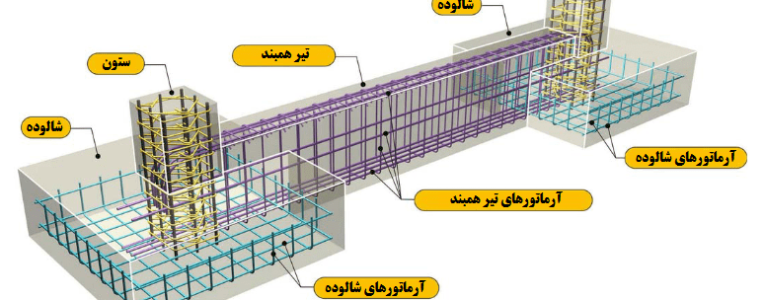

4. Foundation Formwork Execution

Formwork is a critical stage where molds are created to shape the concrete and support reinforcing bars (rebar). Formwork systems also act as temporary retaining structures during pouring.

Common formwork types include:

- Timber Formwork: Cost-effective but less durable.

- Modular Metal Formwork: Durable, reusable, and ideal for large projects.

- Plastic Formwork: Lightweight, moisture-resistant, and comparable to metal formwork in performance.

Concrete formwork systems, such as modular metal or plastic options, offer flexibility and efficiency in modern construction.

5. Concrete Pouring

Once formwork and rebar are in place, concrete is poured. The concrete must have adequate compressive strength (typically 20–30 MPa) and be poured uniformly. Vibrators are used to eliminate air bubbles and ensure a dense, solid structure.

6. Finalization and Maintenance

After pouring, the foundation requires curing to prevent cracking and maintain strength. Curing involves keeping the concrete moist for at least 7 days. Voids around the foundation are filled with sealants or soil to protect against water infiltration and environmental damage.

Key Tips for Foundation Formwork

Formwork is a delicate process that demands precision and expertise. The following tips ensure high-quality formwork:

- Secure Formwork: Ensure formwork is firmly fixed to withstand concrete pressure.

- Accurate Dimensions: Formwork dimensions must match design specifications.

- Easy Assembly/Disassembly: Design formwork for quick setup and removal to save time and costs.

- Proper Sealing: Seal joints to prevent concrete slurry leakage.

- Use Formwork Oil: Apply oil to improve concrete surface quality and ease formwork removal.

- High Durability: Use robust materials to prevent deformation under load.

- Vertical Alignment: Ensure the foundation is perfectly plumb to avoid structural issues.

- Rebar Cover: Maintain adequate spacing between rebar and concrete surface to prevent corrosion.

- Transportability: Choose formwork that can be easily moved with available site equipment.

For large projects,

modular metal formwork ensures safe and efficient formwork execution.

The Role of Rebar in Foundations

Rebar enhances the tensile strength of concrete in foundations. Common types of rebar include:

- Plain Rebar: Used for light loads and general applications.

- Deformed Rebar: Provides better bonding with concrete for heavy loads.

- Alloy Rebar: Corrosion-resistant, ideal for humid environments.

- A2 and A3 Rebar: Specific grades for various structural needs.

Rebar sizes (e.g., 8, 10, 12, 16, 20 mm) are selected based on structural design and load requirements.

Comparison of Foundation Formwork Types

The choice of formwork impacts project quality and cost. The table below compares common formwork types:

| Formwork Type |

Advantages |

Disadvantages |

Applications |

| Timber Formwork |

Cost-effective, widely available |

Low durability, requires skill |

Small projects |

| Modular Metal Formwork |

Durable, reusable |

High initial cost |

Large projects |

| Plastic Formwork |

Lightweight, moisture-resistant |

Higher cost than timber |

Modern projects |

Challenges in Foundation Execution and Solutions

Foundation execution comes with challenges that can be managed with proper planning:

- Weak Soil: Use deep foundations or soil improvement techniques.

- Concrete Slurry Leakage: Ensure tight sealing and use formwork oil.

- Misalignment: Employ precise tools like plumb bobs and lasers.

- High Costs: Opt for cost-effective materials like plastic formwork.

The Role of Modular Formwork Systems

Modern formwork systems, such as

plastic formwork systems and

modular metal formwork, enhance efficiency and durability. These systems support precise concrete pouring, reduce labor time, and are reusable, making them ideal for large-scale projects. For a broader overview, explore

concrete formwork solutions.

Conclusion

The foundation is the backbone of any structure, ensuring stability and longevity. By following proper execution steps, selecting appropriate materials, and using advanced systems like

modular metal formwork and

plastic formwork systems, you can build a robust foundation. Attention to formwork details, soil mechanics, and foundation type selection is key to successful construction projects.

Frequently Asked Questions

What is a foundation, and why is it important?

A foundation transfers building loads to the ground, ensuring stability and preventing settlement or collapse.

What are the types of foundations?

Foundations are divided into shallow (strip, spread, isolated) and deep (piles, caissons).

How can concrete slurry leakage be prevented in formwork?

Tight sealing and formwork oil application prevent slurry leakage.