What is Concrete Formwork and Why It’s Essential in Construction?

Concrete formwork is a temporary or permanent mold used to shape and support freshly poured concrete until it hardens into desired structures like walls, columns, slabs, foundations, or specialty elements such as bridges or pools. It’s the backbone of concrete construction, ensuring precision, strength, and safety.

At Alborz Formwork, we specialize in two primary types: metal concrete formwork—known for its robustness and reusability—and plastic concrete formwork—celebrated for its lightweight design and versatility. Both are proudly manufactured in Iran, offering top-quality solutions for projects ranging from small homes to large-scale infrastructure like dams and high-rises.

Concrete formwork plays a pivotal role in delivering structural integrity and efficiency. For instance, in a Tehran high-rise project, our metal concrete formwork, produced in Iran, shaped 40×40 cm columns with perfect alignment, reducing labor time by 20%. In a Mazandaran villa, our plastic concrete formwork, also made in Iran, created smooth pool walls without rust concerns, cutting maintenance costs in humid conditions.

Whether you need the durability of metal or the portability of plastic, Alborz Formwork provides options to suit every need. Curious about concrete formwork price or ready to purchase from Iran? Contact us today at +98 912 139 0683 or explore our Metal Formwork and Plastic Formwork pages for details!

Concrete Formwork Systems

Concrete formwork is the process of creating a temporary structure or mold that is used to hold wet concrete in place until it hardens and becomes a solid structure. The formwork serves as a support system for the concrete until it reaches its required strength and can support itself.

Here are some important things you need to know about concrete formwork:

Materials used for formwork: The most common materials used for formwork are wood, steel, aluminum, and plastic. Wood is the most traditional material used for formwork, while steel and aluminum are more commonly used for large-scale projects. Plastic formwork is a newer material that is becoming more popular due to its lightweight and reusable properties.

Types of formwork: There are two main types of formwork: traditional formwork and modular formwork. Traditional formwork is built on-site using materials such as wood, while modular formwork is pre-manufactured and can be assembled on-site. Modular formwork is faster to install and can be reused multiple times, making it a more cost-effective solution.

Formwork design: The design of the formwork is critical to the success of the project. The formwork must be designed to withstand the weight and pressure of the wet concrete, and must be able to support any additional loads such as workers and equipment. The formwork design must also take into account the shape and dimensions of the final concrete structure.

Formwork installation: Once the formwork is designed, it must be installed correctly to ensure the concrete is poured in the right position and shape. The installation process must also consider the safety of workers and the stability of the formwork structure.

Removal of formwork: Once the concrete has hardened and reached its required strength, the formwork can be removed. The removal process must be done carefully to avoid damaging the concrete structure.

Reusability of formwork: Depending on the type of formwork used, it may be reusable for multiple projects. Reusable formwork can be a cost-effective solution for construction projects that require the same or similar structures.

Overall, concrete formwork is an important part of the construction process. Proper design, installation, and removal of formwork can ensure the success of a project and the safety of workers.

Types of Concrete Formwork

Materials used for formwork: The most common materials used for formwork are wood, steel, aluminum, and plastic. Wood is the most traditional material used for formwork, while steel and aluminum are more commonly used for large-scale projects. Plastic formwork is a newer material that is becoming more popular due to its lightweight and reusable properties.

Timber Formwork

Timber formwork is a popular choice, as it is reusable and easy to work with. However, it is prone to warping and can be costly in the long run.

Steel Formwork

Steel formwork is durable, and can withstand extreme weather conditions, making it a great choice for large-scale projects. However, it can be costly and requires skilled labor.

Aluminum Formwork

Aluminum formwork is lightweight and easy to assemble. It is a good choice for simple structures and is recyclable. However, it can be costly and may not be suitable for complex designs.

Plastic Formwork

Plastic formwork is lightweight, easy-to-use, and cost-effective. It is suitable for small to medium-sized projects. However, it may not be as durable as other types of formwork.

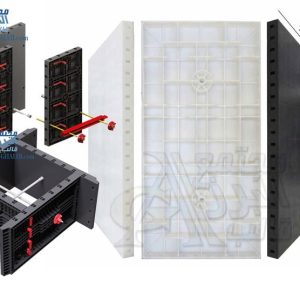

Production of all kinds of concrete molds in Alborz-Ghaleb Complex

Alborz-Ghaleb Complex is one of the leading manufacturers of concrete molds in Iran. This complex offers a variety of products in the field of producing concrete molds, which include the following:

Modular metal concrete formwork

concrete formwork plastic systems

Mixed concrete mold

This collection is able to produce concrete molds with different shapes and dimensions such as rectangular, square, circular, etc. in a customized way. Also, this group uses quality materials to produce concrete molds to produce high quality and long lasting products.

Applications of Concrete Formwork in Construction Projects

Concrete formwork is versatile, supporting a wide range of construction applications. Manufactured in Iran by Alborz Formwork, our systems—both metal and plastic—are designed to meet diverse project demands:

Wall Formwork: Shapes concrete walls of all types—shear walls, retaining walls, or boundary walls—with flat panels and corner units for sharp edges. In a Tehran residential complex, our metal wall forms, made in Iran, delivered seamless 20 cm walls, while plastic forms excelled in a Karaj project for quick setup.

Slab and Beam Formwork: Supports flat slabs and beams, ensuring even, load-bearing surfaces. A Yazd factory used our Iranian-made metal slab forms for a 500 m² pour, while a Shiraz site opted for plastic forms to replace plywood in a humid dala slab setup.

Column Formwork: Creates columns of various sizes and shapes. Our metal forms, produced in Iran, shaped precise 40×40 cm columns in a Mashhad tower, while our plastic prismatic forms (20×20 to 60×60 cm) crafted decorative pillars in an Isfahan villa.

Foundation Formwork: Builds strip or raft foundations with strength and economy. An industrial site in Shiraz used our metal forms, made in Iran, for a robust base, while a Yazd warehouse chose plastic forms for cost-effective portability.

Special Structures: Customizable for bridges, tunnels, pools, or stairs. A Mazandaran pool project used our Iranian-made plastic forms for smooth finishes, while an Isfahan bridge relied on metal forms for curved supports.

The adaptability of our concrete formwork, manufactured in Iran, shines through in real-world use. In a Tehran high-rise, metal forms sped up slab pours by 25%, while plastic forms halved setup time for a Karaj wall.

Why Concrete Formwork is a Construction Cornerstone

Concrete formwork is the foundation of safe, efficient construction, shaping the future of buildings and infrastructure. Poor formwork can lead to leaks, cracks, or collapses—picture a bridge failing due to weak molds!

Manufactured in Iran by Alborz Formwork, our metal concrete formwork offers unmatched strength (up to 80 kN/m²) and reusability (150 cycles), while our plastic concrete formwork provides lightweight flexibility (10-16 kg/m²) and corrosion resistance. Both systems ensure quality finishes, balancing concrete formwork price with performance.

In a Tehran tower, our metal forms, made in Iran, delivered flawless exposed concrete walls, cutting finishing costs by 15%. In Mazandaran’s humid climate, our plastic forms, also produced in Iran, outlasted metal without rust, saving upkeep expenses. With fast assembly—pins for metal, levers for plastic—and local production expertise, Alborz Formwork enhances project outcomes.

Ready to explore concrete formwork price or purchase from Iran? Contact us at +98 912 139 0683 for tailored solutions!

Types of Concrete Formwork Manufactured in Iran by Alborz Formwork

Manufacturing concrete formwork requires precision and expertise, and at Alborz Formwork, we produce both metal and plastic systems in Iran with cutting-edge technology:

Plastic Formwork Manufacturing

Design: Panels (e.g., 60×120 cm) are designed with lever or pin slots, optimized for 80 kN/m² (ABS)—engineered in Iran.

Material Choice: ABS, PP, PE, or recycled polymers are selected—processed locally in Iran.

Injection Molding: Polymers are melted and molded in Iranian machines, producing uniform panels in one step—faster than metal.

Testing: Forms are pressure-tested (80 kN/m² ABS) in our Iranian labs for reliability.

Metal Formwork Manufacturing

Design: Panels (e.g., 50×100 cm) are engineered for walls, columns, or slabs, ensuring 80 kN/m² capacity—designed by Iranian engineers.

Steel Cutting: High-grade steel (Mobarakeh, Gharb, or acid-washed) is cut with CNC machines in our Iranian factories for exact dimensions.

Shaping: Sheets are bent into edge-folded (Aras) or welded (tsme’i) forms—edge-folded for lighter weight, welded for strength—all crafted in Iran.

Welding: Punched edges and stiffeners are welded, tested for durability, showcasing Iranian craftsmanship.

Coating: Anti-rust paint is applied, extending life—produced in our Iranian facilities.

Types of Concrete Formwork Manufactured in Iran by Alborz Formwork

Manufactured in Iran, our concrete formwork includes:

Plastic Formwork Types

Ledge 5 (Pin-Type): 50×100 cm (5.2 kg), white or black, connects to metal, made in Iran for walls (e.g., Tehran apartment).

Lever Ledge 8 (ABS/PP): 60×120 cm (11 kg ABS), red levers, up to 100 uses, produced in Iran for high walls (e.g., Shiraz).

Prismatic Column: 20×20 to 60×60 cm, ~80 kg/set, flexible, manufactured in Iran for columns (e.g., Isfahan villa).

Metal Formwork Types

Welded (Tsme’i): 3 mm steel, 5-6 cm edges, robust for heavy loads, made in Iran for foundations and columns (e.g., Isfahan factory).

Edge-Folded (Aras): Lighter with 2 mm folded edges, smooth finishes, produced in Iran for walls (e.g., Tehran tower).

Ledge 5/6 Modular: Punched edges for fast pinning, versatile, reusable 150 times—crafted in Iran for slabs (e.g., Mashhad).

Benefits and Drawbacks

Plastic Formwork

Benefits: Light (10-16 kg/m²), rust-free, no oiling—produced in Iran for efficiency (e.g., Mazandaran pool).

Drawbacks: Lower strength (80 kN/m² max), non-repairable—replaced at 50% cost by us.

Metal Formwork

Benefits: Strength (80 kN/m²), 150 uses, precise finishes—made in Iran for durability (e.g., Tehran tower).

Drawbacks: Heavy (40 kg/m²), rust risk—needs care, unlike plastic.

Maintenance Tips

Metal: Clean, oil, store dry—our Iranian forms last 150+ uses with care.

Plastic: Clean with water, avoid 80°C+, store dry—made in Iran for simplicity.

For tips or purchase from Iran, call +98 912 139 0683!

Why Alborz Formwork?

Manufactured in Iran, our concrete formwork—metal and plastic—offers quality, affordability, and fast shipping from Tehran, Karaj, Isfahan, and Yazd. Purchase from Iran for top solutions—call +98 912 139 0683!