Metal Formwork – Strength, Precision, and Durability in Construction

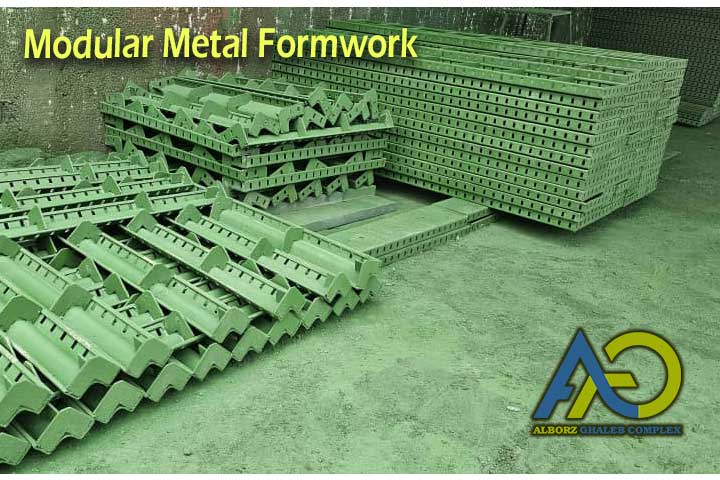

Metal formwork is a strong, reusable, and temporary framework designed to shape freshly poured concrete into various structural elements such as walls, columns, slabs, and foundations. Known as “modular metal formwork”, these systems feature standardized, interlocking panels that provide exceptional strength, longevity, and efficiency. Manufactured in Iran by Alborz Formwork, our high-quality metal formwork is engineered for a wide range of construction projects, from residential buildings to large-scale infrastructure like bridges, tunnels, and dams.

Using metal formwork enhances structural accuracy, safety, and construction speed. For instance, in a high-rise project in Tehran, our modular metal formwork created perfectly aligned 40×40 cm concrete columns with a smooth, professional finish, reducing labor time by 20% compared to traditional wooden formwork. Similarly, in a bridge construction project in Isfahan, our durable formwork withstood high concrete pressures without deformation, ensuring long-term stability. This reliability and efficiency make metal formwork an essential choice for contractors striving for high-quality results.

Applications of Metal Formwork in Construction

Metal formwork is widely used in various construction projects due to its strength, adaptability, and ease of use. Manufactured in Iran by Alborz Formwork, our systems cater to different project needs, including:

- Column Formwork:

Used for shaping concrete columns of different sizes, with adjustable panel connections to withstand high concrete pressure. - Wall Formwork:

Ideal for constructing shear walls, retaining walls, and boundary walls, featuring flat panels and corner units for sharp, clean edges. - Slab and Beam Formwork:

Provides a solid framework for flat concrete slabs and beams, ensuring even surfaces and high load-bearing capacity. - Foundation Formwork:

Designed for strip or raft foundations, delivering a stable and cost-effective base for various structures. - Special Structures:

Fully customizable for complex designs such as bridges, tunnels, and decorative architectural elements.

Get the Best Metal Formwork Prices & Buy from Iran

Looking for competitive metal formwork prices or ready to purchase high-quality Iranian-made formwork? Contact Alborz Formwork today:

👉 Explore more: Check out our Plastic Formwork page to compare different formwork solutions!

The modular design of our metal formwork—featuring standard sizes like 50×100 cm, 100×150 cm, and 200×50 cm—offers incredible flexibility. In a multi-story building project in Mashhad, this modularity, a hallmark of our Iranian manufacturing, allowed workers to assemble forms 30% faster than with non-modular systems, saving valuable time and labor costs. Whether it’s a small home or a massive dam, construction demands precision and durability, and metal formwork from Alborz Formwork delivers both. Want to know the metal formwork price or purchase from Iran? Contact us now at +98 912 139 0683!

Why Metal Formwork is Essential in Construction

Metal formwork is more than just a construction tool—it’s a fundamental element of modern concrete structures, guaranteeing safety, quality, and efficiency in every pour. Inferior formwork can lead to critical failures, such as concrete leaks or structural collapses—imagine a bridge support failing due to weak forms!

Manufactured in Iran by Alborz Formwork, our modular metal formwork is built from high-grade steel, sourced from top Iranian suppliers like Mobarakeh Steel and Gharb Steel. Engineered to withstand heavy concrete loads (up to 80 kN/m²), it delivers flawless, professional results every time. The fast assembly system, using pins and wedges, combined with its impressive reusability (up to 150 cycles with proper maintenance), makes it a cost-effective and reliable choice for contractors worldwide.

Proven Performance in Real Projects

Dam Construction in Mazandaran:

Our Iranian-made metal formwork endured the massive pressure of a 10-meter concrete pour, ensuring a smooth, durable surface that met strict safety regulations.High-Rise Project in Tehran:

With quick setup, our metal formwork cut labor costs by 25%, keeping the project on schedule and within budget.

Versatile Solutions for Every Project

At Alborz Formwork, we specialize in producing high-quality metal formwork for:

✔ Columns – Achieve precise, smooth concrete columns with high durability.

✔ Walls – Form flawless shear walls, retaining walls, and boundary walls.

✔ Slabs & Beams – Ensure even, high-load-bearing surfaces with easy installation.

✔ Foundations – Build strong and stable bases for any structure.

✔ Specialized Structures – Customize formwork for bridges, tunnels, and complex designs.

Get the Best Metal Formwork at Competitive Prices

Looking for affordable and high-performance metal formwork? Manufactured in Iran, our formwork offers exceptional quality at competitive prices.

👉 Compare options: Visit our Plastic Formwork page!

How Metal Formwork is Manufactured in Iran by Alborz Formwork

Manufacturing metal formwork is a precise and meticulous process that combines engineering expertise with high-quality materials to produce reliable and durable construction tools. At Alborz Formwork, our state-of-the-art facilities in Iran follow a step-by-step production process to ensure every piece meets global quality standards.

Step-by-Step Metal Formwork Manufacturing Process

1. Design & Engineering

We begin with detailed engineering plans, defining dimensions such as 50×100 cm panels for walls or custom sizes for columns. Our Iranian engineers calculate load capacities to ensure the formwork can withstand concrete pressures up to 80 kN/m², making them suitable for both local and international construction projects.

2. Steel Selection & Cutting

We source high-grade steel sheets from:

- Mobarakeh Steel (Premium Quality)

- Gharb Steel (Mid-Range Quality)

- Acid-Washed Recycled Steel (Cost-Effective Option)

Using CNC cutting machines, we achieve precise edges and hole punching, all performed in our Iranian manufacturing plants to ensure accuracy and consistency.

3. Shaping the Panels

The steel sheets are then shaped into two main types of panels:

- Edge-Folded (Aras Type): Uses a double-folded 2 mm edge, making it lighter and easier to handle.

- Welded (Tsme’i Type): Features 5-6 cm welded strips, providing superior strength and durability for heavy concrete loads.

Each panel type is designed to maximize efficiency and longevity in construction projects.

4. Welding & Assembly

The cut and shaped panels are then welded together. Skilled Iranian welders ensure:

✅ High-strength joints capable of resisting intense concrete pressure

✅ No deformation during heavy concrete pours

✅ Long-lasting structural integrity

Each welded panel undergoes rigorous quality control before moving to the next stage.

5. Anti-Rust Coating & Finishing

To prevent corrosion and reduce concrete adhesion, each panel is coated with a protective anti-rust layer.

✔ Extends formwork lifespan

✔ Ensures easy cleaning & reuse (up to 120-150 cycles)

✔ Ideal for humid regions like Northern Iran

Final inspections ensure alignment, surface quality, and durability before shipment.

6. Packaging & Distribution

The finished metal formwork is packaged and shipped from our factories in Tehran, Karaj, Isfahan, and Yazd. Our fast logistics ensure quick delivery to customers purchasing metal formwork from Iran.

Why Choose Metal Formwork Over Plastic?

Unlike plastic formwork, which is produced through injection molding, metal formwork undergoes multiple precision-based steps, ensuring superior strength and longevity.

✅ Case Study: Industrial Project in Shiraz

- Our welded formwork, made from Mobarakeh steel, lasted 120+ cycles without wear.

✅ Case Study: Humid Construction Site in Mazandaran

- The anti-rust coating kept the formwork corrosion-free, even in high-moisture conditions.

Looking to Buy Metal Formwork from Iran?

Need a price quote for metal formwork or want to purchase directly from our Iranian factories?👉 Compare alternatives: Visit our Plastic Formwork page!

Types of Modular Metal Formwork Manufactured in Iran by Alborz Formwork

Manufactured in Iran by Alborz Formwork, our modular metal formwork systems are engineered to meet various construction needs, offering strength, efficiency, and reusability. Each type is designed with unique features tailored for specific applications in residential, commercial, and industrial projects.

1. Welded Metal Formwork (Tsme’i Type)

🔹 Specifications:

- Made from 3 mm steel sheets

- Reinforced with welded strips (tsme) for extra rigidity

- Features 5 cm or 6 cm edges for enhanced stability

- Manufactured in Iran at Alborz Formwork’s advanced facilities

🔹 Advantages:

✔ Highly durable, capable of handling heavy concrete loads

✔ Budget-friendly option for cost-conscious contractors

✔ Resistant to deformation, ensuring long-term structural integrity

✔ Locally produced with high-quality Iranian steel

🔹 Applications:

- Foundation work in industrial and commercial projects

- Large concrete columns for high-rise buildings

- Infrastructure projects, such as bridges and tunnels

✅ Case Study: Industrial Project in Isfahan

In a 600 m² factory foundation pour, our welded metal formwork, manufactured in Iran, provided seamless, crack-free concrete surfaces, ensuring structural reliability for long-term durabilit

Manufactured in Iran by Alborz Formwork, our modular metal formwork is engineered for strength, efficiency, and long-term durability. Designed for various construction applications, each system offers unique advantages for contractors, engineers, and builders worldwide.

2. Edge-Folded Metal Formwork (Aras Type)

🔹 Specifications:

- Constructed from 3 mm high-grade steel

- Double-folded 2 mm edges for enhanced stability

- Reinforced with 3-4 mm stiffeners for durability

- Lightweight design, making handling easier on-site

- Manufactured in Iran with advanced precision techniques

🔹 Advantages:

✔ Lighter than welded metal formwork, reducing labor effort

✔ High strength, capable of withstanding heavy concrete loads

✔ Smooth concrete finish, perfect for exposed surfaces

✔ Easier transportation and assembly, a result of Iranian engineering

🔹 Applications:

- Shear walls and boundary walls

- Decorative concrete columns

- Residential slabs and flooring systems

✅ Case Study: Tehran Residential Tower

In a Tehran high-rise project, our Aras metal formwork, proudly manufactured in Iran, was used to cast 20 cm thick walls, delivering a polished, seamless finish that eliminated the need for additional plastering.

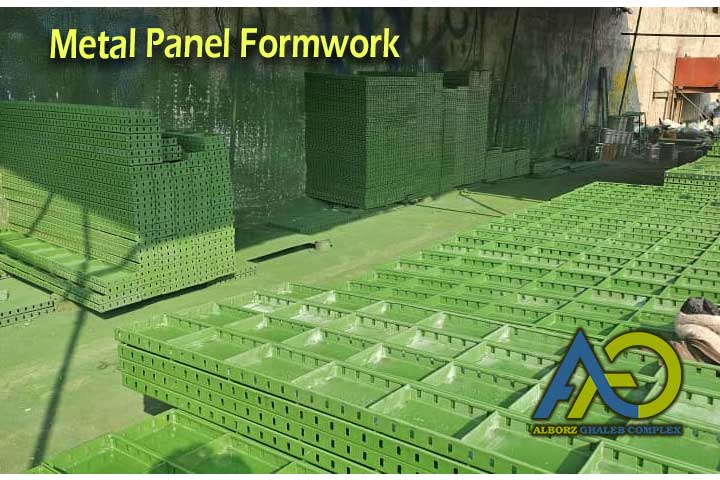

3. Ledge 5 & 6 Modular Formwork

🔹 Specifications:

- Punched-edge panels with 5 cm spacing for quick pinning

- Lobed or star-shaped holes for secure wedge connections

- Adaptable configurations, allowing modular setups

- Locally crafted in Iranian factories for precision and durability

🔹 Advantages:

✔ Maximum flexibility, suitable for diverse projects

✔ Rapid assembly and disassembly, reducing labor costs

✔ Highly reusable (up to 150 cycles) for cost efficiency

✔ Trusted Iranian manufacturing quality, ensuring long-term reliability

🔹 Applications:

- Multi-purpose formwork for walls, columns, slabs, and foundations

- Infrastructure projects, including bridges, tunnels, and industrial structures

✅ Case Study: Mashhad High-Rise Construction

In a high-rise project in Mashhad, our Ledge 5 modular formwork, expertly produced in Iran, reduced slab formwork installation time by 30%, allowing the project to stay on schedule and within budget.

Standard Metal Formwork Sizes

Our modular metal formwork systems, manufactured in Iran, are available in standardized panel sizes, ensuring seamless integration across construction projects:

📌 50×100 cm, 100×150 cm, 200×50 cm (Custom sizes also available)

✅ Case Study: Yazd Bridge Construction

In a bridge project in Yazd, our Ledge 5 forms, produced locally, combined with custom panels, easily shaped complex concrete supports, ensuring structural integrity and smooth finishes.

Metal Formwork Price List (March 2025)

Pricing depends on steel type and formwork method, all manufactured in Iran:

| Formwork Type | Steel Type | Price per kg (IRR) | Typical Weight (kg) |

|---|---|---|---|

| Welded | Acid-Washed | Contact us | 20 |

| Welded | Gharb Steel | Contact us | 20 |

| Welded | Mobarakeh Steel | Contact us | 20 |

| Edge-Folded | Acid-Washed | Contact us | 18 |

| Edge-Folded | Gharb Steel | Contact us | 18 |

| Edge-Folded | Mobarakeh Steel | Contact us | 18 |

📌 Prices are subject to market fluctuations.

📞 For exact metal formwork price or to buy metal formwork from Iran, call us at +98 912 139 0683.

Benefits and Drawbacks of Using Metal Formwork

Benefits of Metal Formwork

✅ Unmatched Strength & Durability

- Withstands heavy loads (up to 80 kN/m²)

- Reusable up to 150 cycles with proper care

- Example: In a Mazandaran dam project, our Iranian-made metal formwork held up under massive concrete pressure, ensuring structural integrity

✅ High Precision

- Delivers smooth, accurate concrete finishes

- Reduces finishing costs by 15%, ideal for exposed concrete in Tehran high-rises

- Manufactured in Iran with precision engineering

✅ Cost-Effective Reusability

- Lowers overall expenses over multiple projects

- Example: A Mashhad contractor reused our metal formwork 130 times, proving its long-term cost efficiency

✅ Rapid Assembly & Installation

- Pin-and-wedge system allows for fast setup

- Saves 20% in construction time in Isfahan projects

- Made in Iran for maximum efficiency on-site

✅ Weather Resistance & Durability

- Anti-rust coating protects against corrosion

- Performs in humid and arid climates (unlike timber, which rots in North Iran)

- Locally manufactured in Iran for reliable, long-lasting performance

✅ Versatility & Adaptability

- Modular design suits walls, columns, slabs, and custom structures

- Example: In Yazd tunnel construction, curved metal formwork, produced in Iran, shaped complex designs with ease

Drawbacks of Metal Formwork

❌ Higher Initial Cost

- More expensive upfront than plastic formwork

- However, cost savings accumulate over time due to higher reusability

- Our Iranian-made metal formwork offers a competitive price advantage

❌ Heavy Weight

- Weighs approximately 40 kg/m², requiring cranes for lifting

- Plastic formwork, at 10-16 kg/m², is easier to move manually

- Best suited for large-scale projects where strength outweighs portability

❌ Corrosion Risk

- Rust can form without proper maintenance

- Unlike plastic, which doesn’t corrode

- Our Iranian metal formwork comes with an advanced anti-rust coating to minimize this risk

❌ Requires Skilled Labor

- Proper training is needed for correct assembly and dismantling

- Unlike plastic formwork, which features simple locking mechanisms

- Alborz Formwork provides expert guidance to ensure easy setup

Conclusion: Why Choose Metal Formwork?

🔹 Metal formwork is the best choice for high-strength, large-scale projects

🔹 Despite its weight and initial cost, its reusability and durability make it highly cost-effective

🔹 Alborz Formwork, manufactured in Iran, delivers top-tier quality at the best price

Maintenance Tips for Metal Formwork Longevity

To extend the lifespan of your metal formwork, manufactured in Iran, follow these essential maintenance steps:

1. Clean After Every Use

- Remove concrete residue with water and a stiff brush.

- Prevents buildup that can affect future pours.

- Example: In a Shiraz project, regular cleaning helped reuse formwork for 120 cycles without loss of quality.

2. Apply Anti-Rust Oil or Coating

- Before storage, apply a thin layer of anti-rust oil to prevent corrosion.

- Especially important in humid climates like Mazandaran.

- Our Iranian-made anti-rust coatings provide extra durability.

3. Store in a Dry, Covered Area

- Keep metal formwork off the ground and store it in a sheltered space.

- Protects against moisture buildup, preventing rust.

- Easier maintenance than timber, which warps over time.

4. Regular Inspections and Repairs

- Check welds and edges for cracks, rust, or deformities.

- Minor repairs, such as re-welding loose edges, can extend usability.

- Unlike plastic formwork, which cracks under stress, metal formwork can be repaired.

🔹 With proper maintenance, our Iranian-manufactured metal formwork lasts up to 150+ cycles!

Why Choose Alborz Formwork for Metal Formwork?

🔹 Manufactured in Iran, Alborz Formwork stands for quality, affordability, and innovation.

🔹 Crafted from premium Iranian steel (Mobarakeh, Gharb), tested for 80 kN/m² strength.

🔹 Fast delivery from Tehran, Karaj, Isfahan, and Yazd—purchasing from Iran is reliable and affordable.

📞 For the latest metal formwork price or to buy metal formwork, contact us at +98 912 139 0683!