What is scaffolding system?

a temporary structure on the outside of a building, made usually of wooden planks and metal poles, used by workers while building, repairing, or cleaning the building.

Scaffolding is also known as staging, and as the name suggests, it is kind of a temporary stage or structure that aims to help people and materials move so that construction projects can be completed. It is highly important that scaffolds are strong and sturdy, because a weak scaffold can result in fatal injuries.

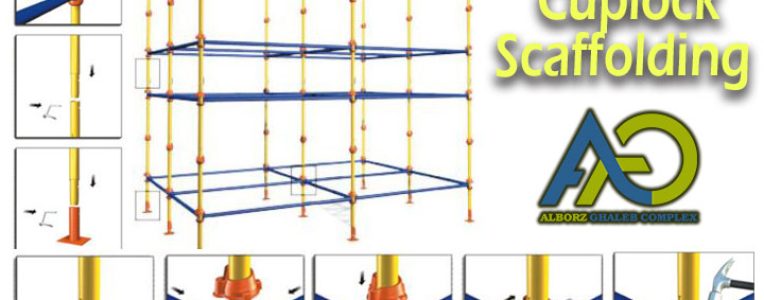

Discovering the Cuplock Scaffolding System

The official name of this scaffolding system is Cuplok, but most people know it as Cuplock.

When it comes to building safety, one of the most underestimated components is scaffolding. Scaffolds provide the necessary support for workers to access and work on the structures being built, which means that choosing the right scaffolding system is critical to ensure the safety of everyone involved in the construction process. In this presentation, we’ll explore everything about the Cuplock Scaffolding System, from its advantages and disadvantages to its use and types.

Cuplock Scaffolding System

The cuplock scaffolding system is a widely used scaffolding system all over the world. Because of its unique locking mechanism, it is an easy to set up system that is fast and economical, therefore so popular. Cuplock scaffolding has been in popular use over the past three decades; it is a fully galvanized system that serves various purposes, and has been chosen by constructors and builders over and over again on some of the world’s most complex projects. The cuplock scaffolding system is a widely used scaffolding system all over the world. Because of its unique locking mechanism, it is an easy to set up system that is fast and economical, therefore so popular. Cuplock scaffolding has been in popular use over the past three decades The Cuplock scaffolding system is a type of modular or systems scaffolding that consists mainly of pre-engineered horizontal and vertical components that combine in a systematic manner to present its users with a temporary structure that proves highly useful in construction projects of the modern world.

The Cuplock System Advantage

Strength & Safety

The Cuplock System is known for its robustness and ability to support heavy loads safely, reducing the risks of accidents and fatalities at construction sites.

Flexibility

The system allows for easy adaptability because of its ability to extend and contract both horizontally and vertically, providing construction designers with numerous possibilities in terms of structures.

Efficiency

The Cuplock Scaffolding System is fast and easy to assemble and disassemble, requiring a minimal number of components and reducing construction time.

Disadvantages of the Cuplock Scaffolding System

Costs

The Cuplock System is relatively more expensive than other scaffolding systems due to the quality of material and engineering design.

Heavy Components

The system’s structure is made of steel, making the components heavy. This makes transportation and assembly labor-intensive and costlier than other systems.

Availability of Parts

Scaffolding systems require a lot of parts, and not all parts might be in stock. This can be a challenge when using the Cuplock System in remote or rural regions.

Cuplock Scaffolding Weight Chart

The weight for cuplock scaffolding vertical/standard spigot| Code | Item | Lengtm(cm) | Weight(kg) |

|---|---|---|---|

| AG-CLV001 | Cuplock Spigoted Standard | 500 | 3.4 |

| AG-CLV002 | Cuplock Spigoted Standard | 1000 | 6.1 |

| AG-CLV003 | Cuplock Spigoted Standard | 1500 | 8.7 |

| AG-CLV004 | Cuplock Spigoted Standard | 2000 | 11.4 |

| AG-CLV005 | Cuplock Spigoted Standard | 2500 | 14 |

| AG-CLV006 | Cuplock Spigoted Standard | 3000 | 16.6 |

Cuplock Scaffolding Weight Chart

Cuplock Scaffolding Ledger / Horizontal| Code | Item | Lengtm(cm) | Weight(KG) |

|---|---|---|---|

| AG-CLH001 | Cuplock Spigoted Standard | 83 | 3.4 |

| AG-CLH002 | Cuplock Spigoted Standard | 105 | 4.2 |

| AG-CLH003 | Cuplock Spigoted Standard | 127 | 5 |

| AG-CLH004 | Cuplock Spigoted Standard | 152 | 5.9 |

| AG-CLH005 | Cuplock Spigoted Standard | 183 | 7 |

| AG-CLH006 | Cuplock Spigoted Standard | 244 | 9.2 |

| AG-CLH007 | Cuplock Spigoted Standard | 305 | 11.4 |

The advantages of using hammer scaffolding are as follows:

1- Ease and speed in opening and closing and not needing a wrench to close connections

As compared to traditional scaffolding systems, the Cuplock scaffolding system has proven itself to be the fastest of all. Because it is so easy and simple to set up, it saves a lot of time and money. This makes it a popular choice among builders and contractors who are always looking to minimize costs and save time. Compared to tube and fittings, Cuplock is known to have saved time by around 30 to 50%.

2 – Can be used in scaffolding facades of buildings

Cuplock is a flexible and adaptable scaffolding system that can be used to make a wide variety of structures which serve useful for construction, refurbishment or maintenance. These structures include facade scaffolds, birdcage structures, loading bays, curved structures, staircases, shoring structures, and mobile towers. Hop-up brackets let workers easily install work platforms at a half meter increment below or above the main deck that gives finishing trades – such as painting, flooring, plastering – flexible and easy access without disrupting the main scaffold.

4- Heavy load in the formwork of concrete slabs

6- Ease of transportation due to the lightness of the parts

Cuplock tube is comparatively lighter than regular tubes, and it is palletised, which makes it easy to transport, handle, and store. Cuplock system can be stored both on site or in the yard, and is least likely to get stolen or lost.

Although the Cuplock scaffolding system is a heavy-duty system, it is surprisingly easy and simple to erect. It requires the least amount of wedge connectors and loose fittings. Standard horizontals are used as guardrails, transoms, and ledgers. The Cuplock scaffolding structure automatically aligns itself when the base lift is levelled. Cantilevers, staircases, and inside platforms can be easily created using components that are specially designed for the purpose.

Production of all kinds of Cuplock Scaffolding System in Alborz-Ghaleb Complex

Alborz-Ghaleb Complex is one of the leading manufacturers of Cuplock Scaffolding System in Iran. This complex offers a variety of products in the field of producing Scaffolding . This collection is able to produce Cuplock Scaffolding with a customized way. Also, this group uses quality materials to produce Cuplock Scaffolding System to produce high quality and long lasting products.

Methods of Using the Cuplock Scaffolding System

Assembly

The first step is to analyze the structure and plan the scaffolding structure to double-check that the system arrives on site in the right configuration. A stable and level foundation is essential for scaffolding assembly to occur effectively. The Cuplock System can be assembled from the ground and gradually lifted up, making it easy to work from the top to bottom of the scaffold as construction continues.

Dismantling

When the project comes to a close, the scaffolding system must be taken apart. This process is like assembly in reverse, but it may necessitate additional time and labor. Contractors should ensure that workers take down the scaffold properly, avoiding any harm to themselves, the structure, or the environment.

Inspection and maintenance

Before and during use, the scaffolding system must be inspected to ensure its stability and safety. While in use, Cuplock scaffolding requires minimal outside maintenance, with one of the few maintenance requirements being periodic touch-up of paint to protect the steel from corrosion.

Installation/Locking Procedure

The distinctive node-point locking device is at the core of the Cuplock scaffolding system. Four horizontal tubes can be safely attached to the standard or vertical tube, and locked firmly in place with a single blow of hammer. Fixed lower cups are welded at half a meter intervals to the standards. Sliding upper cups drop over the ledgers’ blade ends and rotate to firmly lock them into place. There are no loose clips, wedges, or bolts involved in this procedure. Cuplock’s node-point is revolutionary, and makes it faster and easier than any other scaffolding system. Furthermore, the lack of loose components makes it a robust scaffolding system, and its galvanized surface makes it almost immune to damage and corrosion. Cuplock is a zero maintenance scaffolding system, that saves time, money and energy.

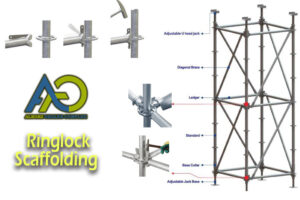

Components of Cuplok

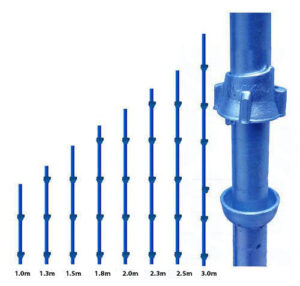

These are vertical

tubes that use lower fixed cups at half a meter intervals with rotating cups on the top. These can firmly hold together up to four components. Verticals come with and without spigots, adding to the flexibility of Cuplock scaffolding system. Verticals without spigots weigh lighter than the one with spigots. Standards are made of 40 mm NB tubes and can be used for access or support. Verticals are available in these sizes: 500 mm, 1000 mm, 1500 mm, 2000 mm, 2500 mm, and 3000 mm.

Cuplock horizontals

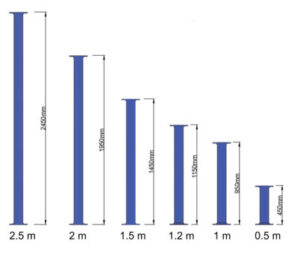

include ledgers and transoms, are also made of 40 mm NB tubes, and are so robust that they require zero maintenance. Horizontal tubes have forged blade ends that allows simple and quick assembly. The blade ends of the horizontals fit into the cup of the vertical tube, ensuring a strong assembly. Normal horizontals can also serve as guard-railings in a staircase tower. Ledgers come in the following standard sizes, but they can also be customized according to your requirement: 500 mm, 1000 mm, 1250 mm, 1500 mm, 2000 mm, and 2500 mm.

Adjusting screw jack

are highly durable and very efficient. The universal jack is used as an adjustment part, and can be inserted at the bottom or top of a scaffold support structure. They have an adjustment of up to half a meter, and accommodate differences in ground level, as well as to keep the structure leveled. Adjusting screw jack is used in conjunction with adapters, foreheads, and base plates. When fully supported, Adjusting screw jacks can take on the entire capacity of Cuplock scaffolding system.

Cuplock vs. Other Scaffolding Systems

Cuplock System

Advantages

Faster assembly

Minimal components

Flexible

Easy to assemble and disassemble

Disadvantages

Relatively expensive

Heavy components

Parts availability

Scaffolds made of pipes and couplers

Advantages

Low cost

Easy installation

Disadvantages

Less flexible in terms of height and length

Additional time is required for assembly and disassembly

Requires more components than other systems

Steel frame scaffolding

Advantages

Lightweight

Durable

Can support heavy loads

Disadvantages

Costly and difficult to transport and assemble

Less flexible in terms of adaptability to different structure configurations

Conclusion

The Cuplock Scaffolding System is one proven method for ensuring the safety of workers on construction sites. Its versatility, strength, and flexibility make it one of the best scaffolding systems on the market. However, contractors and workers must weigh the benefits versus the drawbacks of the system to see if it is suitable for their particular project needs. Overall, the Cuplock Scaffolding System provides a stable, safe, and cost-effective solution that has proven its ability to support and safeguard workers in the construction industry.