Introduction

Roofs are a fundamental component of any building, playing a critical role in ensuring safety, structural integrity, and overall functionality. In recent years, the demand for fast, cost-effective, and lightweight construction methods has led to the rise of innovative roofing systems like the Kermit roof. Combining traditional materials with modern engineering, the Kermit roof offers a versatile and efficient solution for various construction projects. Produced in two distinct types—Kermit joist and block roof and Kermit composite roof—this system has gained popularity due to its unique advantages. In this article, we delve into the specifics of these two types, their benefits, and the detailed steps involved in their execution, providing valuable insights for engineers, builders, and project managers aiming to optimize their construction processes.

Types of Kermit Roofs

The Kermit roof system is available in two primary variations, each tailored to specific project requirements and structural conditions. Below, we explore these types in detail.

Kermit Joist and Block Roof

This type of Kermit roof is designed to be self-supporting, eliminating the need for shoring during installation. This characteristic significantly boosts execution speed, making it a preferred choice for time-sensitive projects.

Features of Kermit Joist and Block Roof

One standout feature is the 75 cm center-to-center spacing of the joists, which reduces concrete consumption by approximately 20% compared to similar systems. This reduction not only lowers material costs but also results in a lighter overall structure. Additional benefits include ease of installation, lightweight design, and seamless integration with the building’s framework. These qualities make it an excellent option for residential and commercial buildings. Pairing this system with tools like Concrete Formwork enhances precision and ensures a high-quality finish during execution.

Execution Steps for Kermit Joist and Block Roof

- Joist Installation: Pre-fabricated Kermit joists are placed on the main beams.

- Block Placement: Lightweight blocks (e.g., clay or polystyrene) are positioned between the joists.

- Reinforcement: A rebar mesh is laid over the blocks and joists to enhance strength.

- Concrete Pouring: Concrete with a specified strength (typically 350 kg/cm²) is poured and leveled with a trowel.

The absence of shoring requirements streamlines these steps, allowing for rapid and efficient construction.

Kermit Composite Roof

Lightweight construction has become a top priority in modern building practices. As a result, composite roofing systems have gained widespread adoption in recent years, with the Kermit composite roof standing out as an optimized solution.

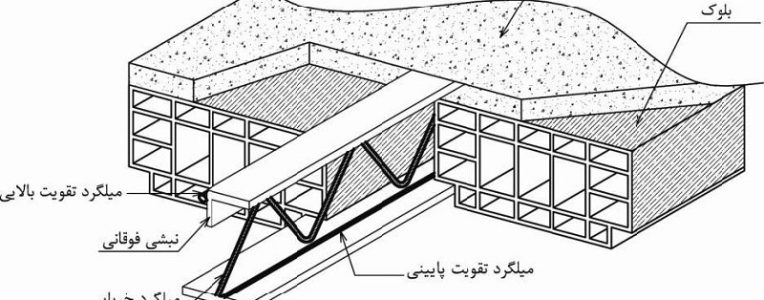

Features of Kermit Composite Roof

The Kermit composite roof utilizes open-web joists with a geometrically efficient design, reducing steel consumption compared to conventional composite roofs. Additionally, filling the joist webs with concrete minimizes roof vibrations, improving acoustic performance and seismic resilience. These attributes make it ideal for high-rise buildings and large-scale projects where stability and efficiency are paramount.

Benefits of Kermit Composite Roof

- Steel Efficiency: Optimized joist design cuts down on steel usage, lowering costs.

- Reduced Vibrations: Concrete-filled joists enhance structural stability.

- Fast Execution: No need for shoring accelerates the construction timeline.

For enhanced durability and accuracy, integrating Concrete Formwork Plastic Systems into the process provides a lightweight and robust alternative to traditional formwork materials.

General Benefits of Kermit Roofs

Whether implemented as a joist and block system or a composite design, the Kermit roof offers a range of advantages that set it apart from conventional roofing methods.

Key Advantages

- No Shoring Required: Saves time and reduces labor costs.

- Warranty Provided: Ensures quality and long-term reliability.

- Speed and Ease of Execution: Ideal for projects with tight schedules.

- Uniform Underside: Offers a clean and aesthetically pleasing finish.

- Structural Integration: Enhances overall building strength.

- Multi-Roof Execution: Allows simultaneous construction of multiple floors.

- Lighter Weight: Reduces dead load compared to similar systems.

- Larger Span Capability: Provides flexibility for expansive designs.

- Civil Liability Insurance: Covers workers during execution for added safety.

These benefits make the Kermit roof a cost-effective and practical choice across various construction scenarios.

Composite Roof: A Closer Look

The composite roof represents a modern approach to roofing, blending lightweight materials with high performance.

Components of Combineet Roof

The Combineet roof comprises steel beams, concrete with a strength of 300 kg/cm², rebar grids (reinforcement), and custom shear connectors. Notably, it uses only one-tenth of the steel required by traditional roofs, while offering superior resistance due to its optimized design.

Execution Steps for Combineet Roof

- Beam Layout: The structural beam plan is completed as designed.

- Shear Connector Installation: Custom shear connectors, made from two No. 10 angles, two 10 mm thick plates (one between the angles and one as a gusset), are welded at a minimum spacing of 40 cm to resist shear forces.

- Rebar Placement: A rebar grid is installed across the roof, with concrete fillets only above the beams (as illustrated).

- Formwork Setup: Wooden or metal formwork is placed beneath the roof.

- Concrete Pouring: Concrete is pumped over the rebar, vibrated, and smoothed with a trowel for a uniform surface.

Shear Connector Design

The shear connectors, uniquely engineered for this system, consist of two angles and plates welded together to form a robust unit. This design significantly enhances shear resistance while minimizing material use, a key factor in the system’s efficiency.

Finishing with False Ceiling

To cover the underside and concrete fillets, a false ceiling (e.g., gypsum panels) is installed. The roof’s thickness, typically at least 980 mm, and shear connector height (20-60 cm) vary based on structural calculations.

Benefits of Combineet Roof

The Combineet roof stands out with its innovative features, offering a range of practical advantages.

Key Benefits

- Vibration-Free: Its integrated design ensures minimal vibrations.

- Low Steel Consumption: Uses one-tenth the steel of other systems.

- High Strength: Optimized structure provides exceptional durability.

- Lightweight and Cost-Effective: Reduces both weight and expenses.

- Uniform and Integrated: Delivers a seamless and attractive finish.

- Fast and Easy Execution: Speeds up construction timelines.

- No Shoring Needed: Cuts down on setup time and costs.

Incorporating Concrete Formwork Plastic Systems into the process enhances execution quality, offering a durable and lightweight alternative to conventional formwork.

Conclusion

The Kermit roof, available in joist and block, composite, and Combineet variations, represents a modern and efficient approach to construction. By reducing structural weight, accelerating execution, and optimizing costs, this system has become a top choice for builders worldwide. Its integration with advanced tools and innovative designs, such as custom shear connectors and polymer formwork, further elevates its effectiveness. Given its numerous advantages, the Kermit roof is poised to play an increasingly significant role in the future of construction, particularly in regions like Iran, where demand for efficient and resilient building solutions continues to grow.