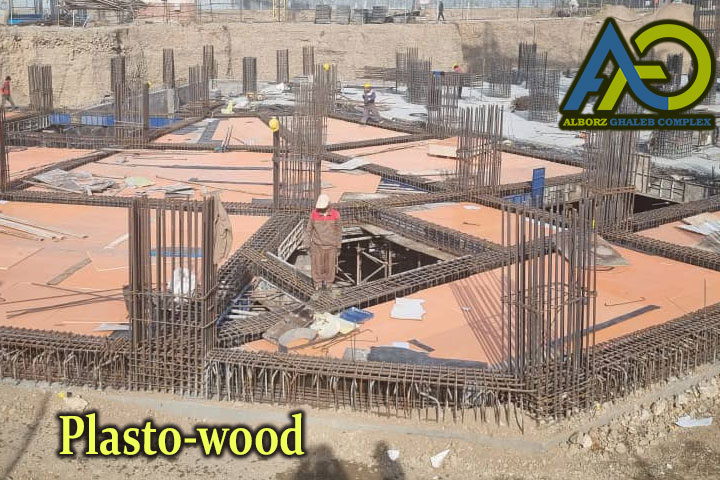

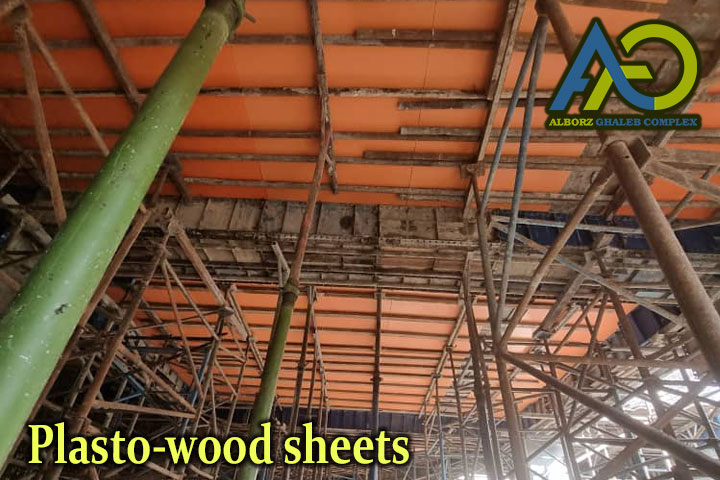

Plasto-wood plastic ceiling molds are a suitable alternative to plywood.

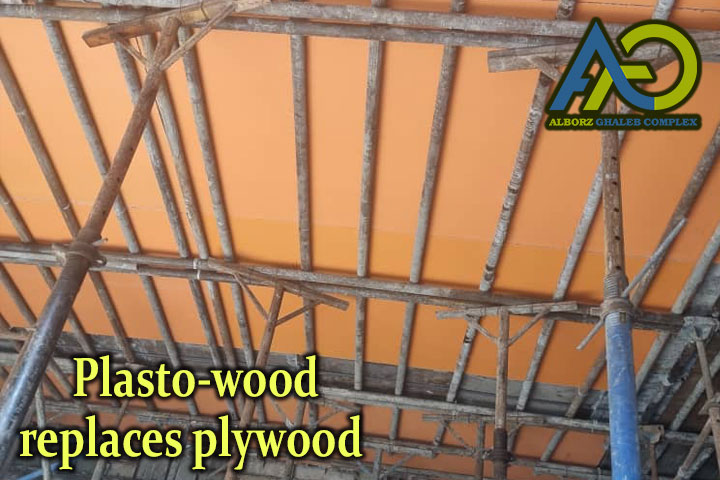

Plasto-wood plastic ceiling molds are an excellent alternative for executing concrete slab ceilings. Typically, plywood, metal sheets, Russian wood, or metal molds are used for this purpose. However, due to the moisture present in the concrete and the humid air in northern and southern regions of Iran, these plywood layers lose their adhesive strength over time, causing them to separate and swell, ultimately losing their structural integrity. Additionally, metal molds and sheets require oiling because concrete tends to stick to them, and the moisture in the concrete can cause the metal to corrode.

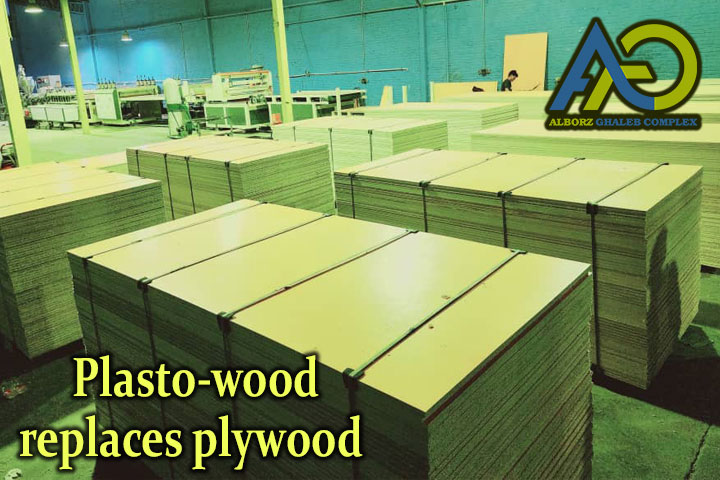

Plasto-wood sheets are a suitable alternative

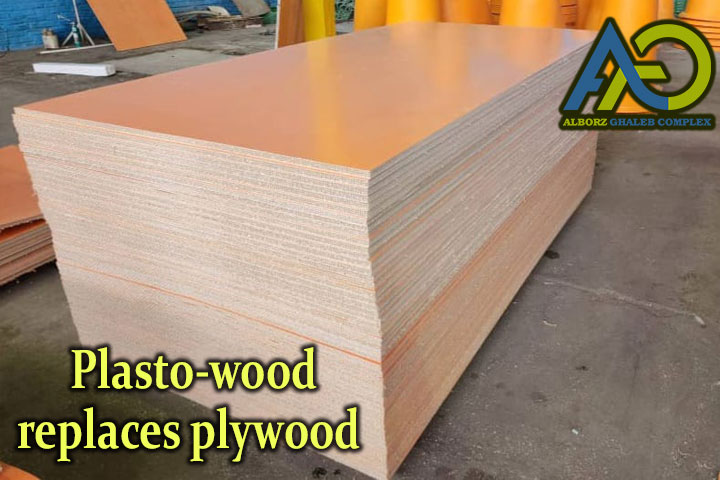

Plasto-wood, also known as plastic wood, is an innovative material that serves as a suitable alternative to plywood for ceiling molds. This composite material is made from a combination of plastic and wood fibers, offering several advantages over traditional plywood:

- Durability: Plasto-wood is more resistant to moisture, insects, and rot compared to plywood, making it ideal for use in environments where these factors are a concern.

- Strength and Stability: The combination of plastic fibers results in a material that is strong and stable, less prone to warping or splitting over time.

- Low Maintenance: Plasto-wood requires less maintenance than plywood. It does not need to be painted or sealed regularly to maintain its appearance and structural integrity.

- Sustainability: Many plasto-wood products are made from polymeric materials, making them a more environmentally friendly option compared to traditional wood products.

- Ease of Installation: Plasto-wood can be easier to work with than plywood. It can be cut, shaped, and installed using standard tools, and often comes in forms that are designed to be easy to handle and install.

By offering these benefits, plasto-wood provides a practical and efficient alternative to plywood for ceiling molds and other construction applications.

.

Advantages of Plasto-wood Sheets

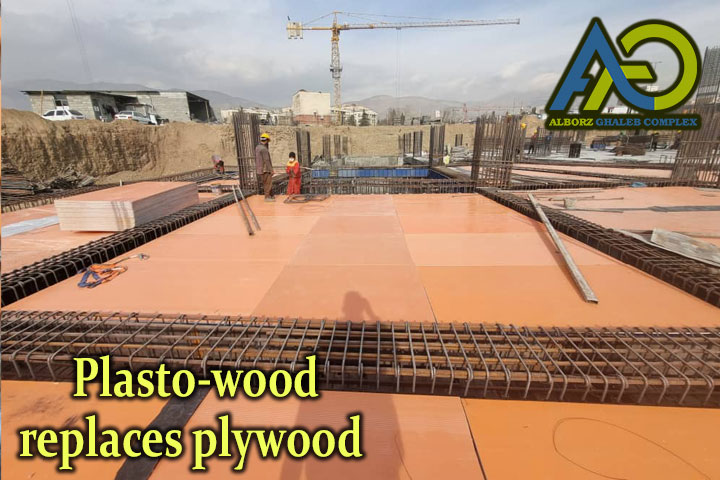

Lightweight: Plasto-wood sheets are significantly lighter than metal molds, making them easier to transport and handle.

Moisture Resistance: Unlike plywood and metal, Plasto-wood is resistant to moisture, making it ideal for use in humid environments.

Durability: Plasto-wood does not warp, swell, or lose its structural integrity over time, even in the presence of water or humid conditions.

No Oiling Required: Plasto-wood sheets do not require oiling, unlike metal molds which need to be oiled to prevent concrete from sticking and to avoid corrosion.

Easy to Connect: These sheets can be easily connected with nails, simplifying the installation process.

Environmental Resistance: Plasto-wood is resistant to the environmental factors that typically degrade plywood and metal, such as humidity and water.

A Plasto-wood sheet measuring 122*244*18 mm weighs approximately 31 kg, which is much lighter than metal molds. This makes Plasto-wood sheets easier to transport and work with. The Plasto-wood ceiling sheet, suitable for slab ceilings, measures 122*244 mm and can be easily connected with nails.

Plasto-wood sheets are a suitable alternative to plywood.

Plastic Plasto-wood sheets are a very suitable alternative to various materials used in the execution of concrete slab ceilings. These plastic molds, due to their moisture-resistant plastic composition, can be easily used in humid areas. Another advantage of plastic ceiling molds is that they do not require oiling.