Introduction to Ringlock Scaffolding

Ringlock scaffolding is a modern system that provides a safe and efficient solution for construction and maintenance projects. Unlike traditional scaffolding methods, which rely on bolts and nuts for assembly, ringlock scaffolding utilizes a unique locking mechanism, offering superior stability and flexibility.

In the construction world, efficiency and safety are paramount. One of the most versatile and reliable tools in a builder’s arsenal is ringlock scaffolding. Let’s delve into why this innovative system is transforming construction sites worldwide.

Streamlined Setup: The Foundation of Efficiency

Ringlock scaffolding offers unparalleled ease of setup, allowing construction crews to save precious time and resources. With its modular design, components seamlessly lock into place, eliminating the need for cumbersome bolts and clamps. This means quicker assembly, fewer delays, and ultimately, a more efficient workflow.

Versatility Redefined: Adaptable for Any Project

From high-rise buildings to intricate structures, ringlock scaffolding adapts effortlessly to diverse construction needs. Its modular nature enables quick adjustments in height, width, and configuration, making it suitable for projects of any scale or complexity. This adaptability not only enhances productivity but also ensures optimal safety for workers at every stage of construction.

Rock-Solid Stability: A Foundation Built on Safety

Safety is non-negotiable in the construction industry, and ringlock scaffolding delivers on this front with unwavering reliability. Engineered for maximum stability, its sturdy design can withstand heavy loads and adverse weather conditions, providing a secure platform for workers to perform their tasks with confidence. With ringlock scaffolding, safety isn’t just a priority—it’s a guarantee.

Efficiency Through Innovation: Ringlock Scaffolding in Action

Imagine a construction site where every component fits seamlessly together, where setup is swift, and safety is uncompromised. This is the reality with ringlock scaffolding—a game-changer in the world of construction. With its unmatched versatility, rock-solid stability, and streamlined setup process, this innovative system is revolutionizing how buildings are erected, setting new standards for efficiency and safety across the globe.

Advantages of Ringlock Scaffolding

Safety and Stability

Ringlock scaffolding is engineered to meet stringent safety standards, providing a secure working platform for workers at various heights. The interlocking design ensures stability, minimizing the risk of accidents and injuries on the job site.

Versatility and Flexibility

One of the key advantages of ringlock scaffolding is its versatility. With modular components that can be easily configured to suit different project requirements, ringlock scaffolding can adapt to diverse environments and structures, offering unmatched flexibility in construction.

Time and Cost Efficiency

Ringlock scaffolding facilitates rapid assembly and dismantling, saving valuable time and labor costs on the job site. The efficiency of the system translates to increased productivity, enabling construction projects to stay on schedule and within budget.

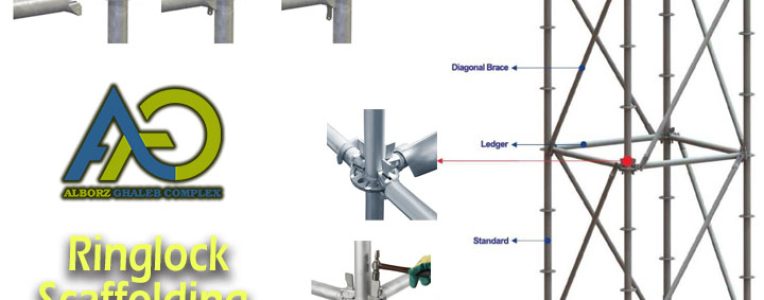

Components of Ringlock Scaffolding

Ringlock scaffolding consists of several essential components, each serving a specific function in the assembly process:

- Standard: Vertical tubes that form the main support structure of the scaffold.

- Ledger: Horizontal tubes that connect the standards and provide additional support.

- Diagonal Brace: Angled tubes that reinforce the scaffold, enhancing stability and rigidity.

- Base Collar: Adjustable bases that secure the scaffold to the ground and ensure level placement.

- Rosette: Circular discs with multiple attachment points for connecting standards, ledgers, and braces.

Assembly Process of Ringlock Scaffolding

Step 1: Prepare the Ground

Before assembling the ringlock scaffold, ensure that the ground surface is flat, stable, and free from any obstacles or debris.

Step 2: Install Base Collars

Attach the base collars to the standards and adjust them to the desired height, ensuring proper alignment and stability.

Step 3: Attach Standards and Ledgers

Insert the standards into the base collars and secure them in place using the rosettes. Then, connect the ledgers horizontally between the standards to form the scaffold framework.

Step 4: Add Diagonal Braces

Install diagonal braces diagonally between the standards and ledgers, reinforcing the scaffold structure and preventing lateral movement.

Step 5: Secure the Scaffold

Once all components are in place, double-check the connections and ensure that the scaffold is securely anchored to the ground. Conduct a thorough inspection to verify the stability and safety of the assembly.

Applications of Ringlock Scaffolding

Ringlock scaffolding is widely used across various industries and applications, including:

- Construction Sites: Ideal for building construction, renovation, and maintenance projects of all sizes.

- Industrial Maintenance: Provides access for equipment installation, repairs, and maintenance in industrial facilities.

- Shipbuilding and Offshore: Offers a safe and stable working platform for ship construction, repair, and maintenance activities.

- Event Staging: Used for temporary structures such as stages, platforms, and grandstands for events and performances.

Comparison with other Scaffolding Systems

Ringlock vs. Cuplock

While both systems offer similar advantages in terms of speed and versatility, ringlock scaffolding is preferred for its enhanced stability and easier assembly process.

Ringlock vs. Tube and Clamp

Ringlock scaffolding provides a more secure and stable solution compared to tube and clamp scaffolding, making it suitable for projects that require higher load-bearing capacity and safety standards.

Maintenance and Safety Tips

To ensure the longevity and safety of ringlock scaffolding, follow these maintenance and safety guidelines:

- Perform regular inspections to check for any signs of damage or wear.

- Use appropriate personal protective equipment (PPE), including helmets, harnesses, and safety shoes.

- Provide comprehensive training for workers on the proper assembly, use, and dismantling of the scaffold.

Conclusion

Ringlock scaffolding offers a superior solution for construction and maintenance projects, combining safety, versatility, and efficiency in one system. With its innovative design and modular components, ringlock scaffolding continues to be the preferred choice for contractors and workers worldwide.

FAQs

-

Is ringlock scaffolding suitable for both indoor and outdoor projects?

- Yes, ringlock scaffolding can be used for a wide range of projects, both indoors and outdoors, thanks to its versatility and adaptability.

-

How does ringlock scaffolding compare to traditional scaffolding methods?

- Unlike traditional methods that rely on bolts and nuts for assembly, ringlock scaffolding features a unique locking mechanism, offering superior stability, flexibility, and efficiency.

-

What safety measures should be followed when using ringlock scaffolding?

- Workers should wear appropriate personal protective equipment (PPE), undergo thorough training on scaffold assembly and use, and conduct regular inspections to ensure safety compliance.

-

Can ringlock scaffolding be customized for specific project requirements?

- Yes, ringlock scaffolding is highly customizable, with modular components that can be configured to suit different project needs and specifications.

-

What are the advantages of choosing ringlock scaffolding over other scaffolding systems?

- Ringlock scaffolding offers advantages such as enhanced safety, faster assembly and dismantling, greater versatility, and superior stability compared to other scaffolding systems.